DIY Troubleshooting Tips for Common Lift Issues

Identifying Common Lift Issues

Elevators, like any mechanical system, can occasionally face issues. However, many common lift problems can be addressed with some basic troubleshooting. Knowing how to identify these issues can save time and ensure the lift operates smoothly.

Lift Not Moving

If the lift isn't moving, it might be due to a power failure or circuit breaker issue. First, check if the lift has power. Ensure the main power switch is on and inspect the circuit breaker for any tripped switches. Reset if necessary.

Another potential cause is the doors not closing properly. Modern lifts often have sensors that prevent movement if the doors aren't completely shut. Inspect the door tracks and remove any obstructions.

Unusual Noises

Unusual noises, such as grinding or squeaking, can indicate mechanical issues. These sounds may result from worn-out parts or insufficient lubrication. Begin by checking the lift's guide rails and applying lubricant if needed.

If the noise persists, it might be due to a misaligned or worn-out pulley. In such cases, it's advisable to contact a professional for further inspection and repair.

Slow Lift Movement

A slow-moving lift can be frustrating for users. This issue often relates to the lift’s hydraulic system or motor efficiency. Start by checking the hydraulic fluid levels and topping up if necessary. Ensure there are no leaks in the system.

Also, inspect the motor for any signs of wear or overheating. A malfunctioning motor may require professional servicing to restore optimal lift speed.

Irregular Stopping

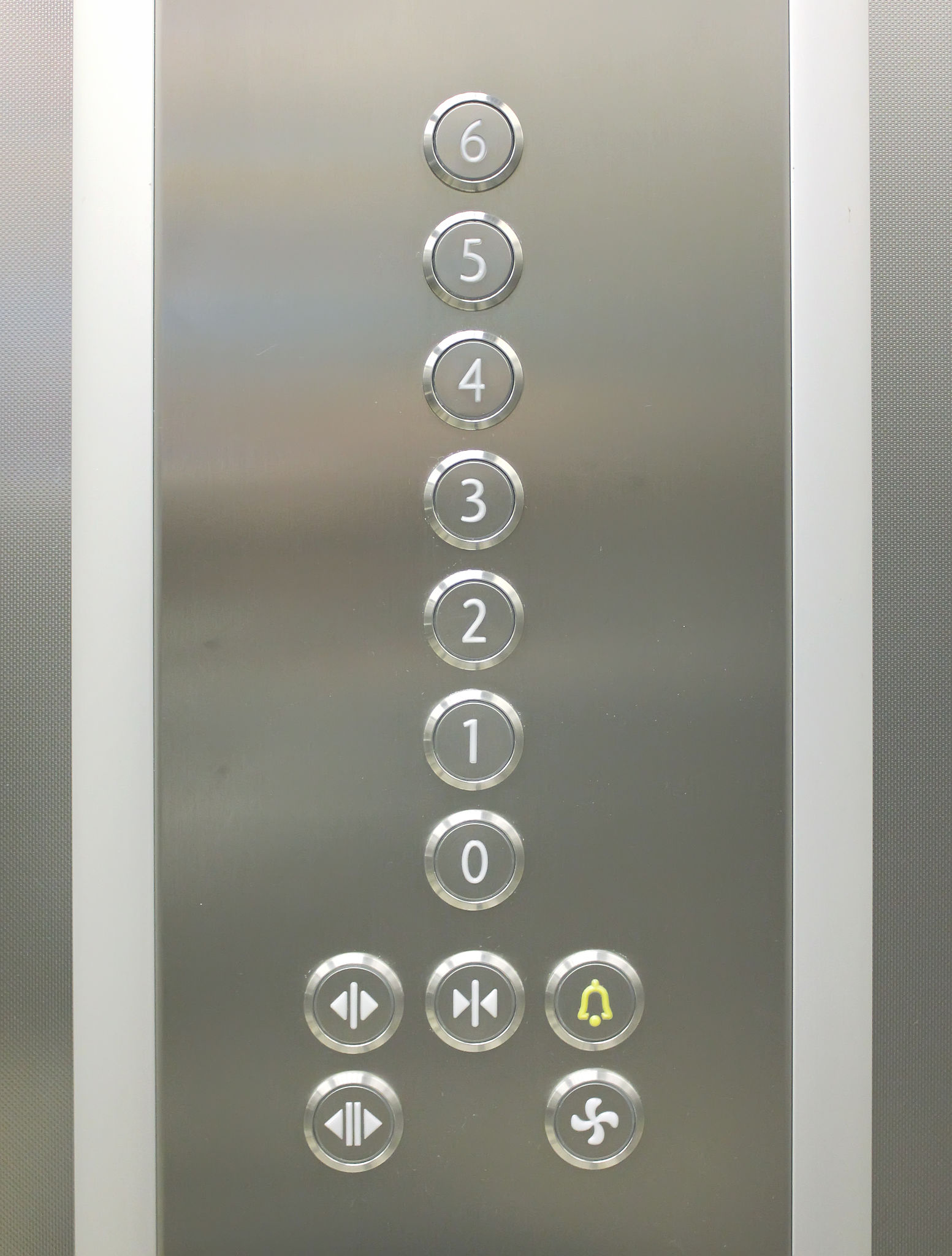

When a lift stops irregularly or at incorrect floors, it could be due to sensor or alignment issues. Ensure that the lift's floor sensors are clean and free from dust or debris, which can interfere with signals.

Additionally, check the alignment of the lift car with the floor levels. Misalignment can cause abrupt stops and affect user safety. Adjustments may be needed to correct this problem.

Regular Maintenance

While DIY troubleshooting can resolve many lift issues, regular professional maintenance is crucial for safety and longevity. Scheduled inspections by certified technicians help identify potential problems before they escalate, ensuring continuous, reliable operation.

By combining these troubleshooting tips with routine maintenance, lift owners can enhance performance and reduce downtime, creating a safer and more efficient environment for all users.